Basic Info.

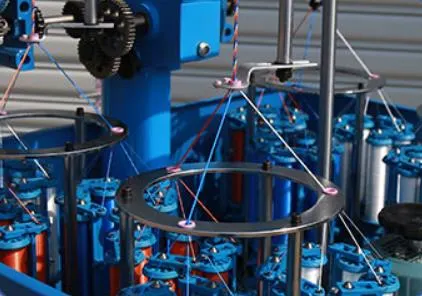

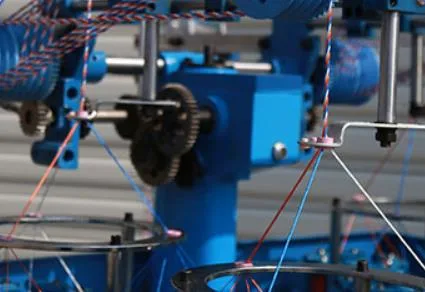

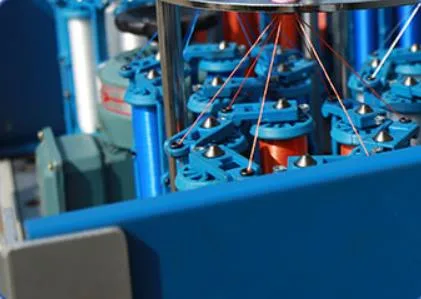

Product Description

Production Description

Main Parts

| No. | Name | Qty | No. | Name | Qty |

| 1 | oscillating pin | 4 | 16 | Fuse | 3 |

| 2 | oscillating wheel | 2 | 17 | Tools | 1 |

| 3 | Corner piece on swing rod seat | 2 | 18 | Bolts | 1 |

| 4 | Ratchet | 1 | 19 | Planetary wheel bearing | 8 |

| 5 | upper spines rod | 2 | 20 | sizing die | 3 |

| 6 | Down spines rod | 2 | 21 | Pitch gear | 1 set |

| 7 | Flat spring | 2 | 22 | Alarm piece | 3 |

| 8 | coil set torsional spring | 23 | nylon tray | 32 | |

| 9 | upper tension spring | 8 | 24 | oscillating bar axle | 2 |

| 10 | Down tension spring | 8 | 25 | stainless steel wire rack | 2 |

| 11 | Spindle wheel (big) | 2 | 26 | 0.5Afuse wire | 2 |

| 12 | Spindle wheel (small) | 2 | |||

| 13 | planetary wheel | 4 | |||

| 14 | gear shaft | 4 | |||

| 15 | nylon slide | 32 |

Specifications

| No. | Name | Unit | Technical Data |

| 1 | Braiding type and braiding direction | 2/2 , Vertical | |

| 2 | Haul-off | Wheel capstan with diameter of 980mm | |

| 3 | Carrier No. | 16 carriers in total (8 upper carriers , 8 down carriers)(for Cu wire ≤5KG, iron wire ≤4.5KG) | |

| 4 | Carrier size (capacity) | Ф110*Ф48*100*110, 32 carriers are equipped for each braiding machine | |

| 5 | Rotation of host machine | rpm | 8-80RPM |

| 6 | Braiding pitch distance range | MM | 10.0~100 |

| 7 | Braiding outer diameter | MM | ≤Φ25,with 15,20,25mm 3set mould |

| 8 | Max braiding speed | M/h | Normal production speed is 70%-80% of the maximum speed |

| 9 | metallic wire diameter | MM | Range: copper wire φ 0.15- φ 0.50, iron wire φ 0.12- φ 0.40, stainless steel wire φ 0.10- φ 0.40, special specifications such as φ 1.0 below the copper wire, iron wire 1-3 can also be woven, at the same time, the machine can also be woven spinning fiber yarn, polyester silk and other non-metallic wire. |

| 10 | Lubrication way | 2.5L oil pump,1pcs,Automatic oiling | |

| 11 | Size of pay-off and take-up | MM | φ1250~φ2000 Choice by customers |

| 12 | Electric form | The pay-off and take-up adopts electric lifting, smooth rod wiring and torque motor winding. There are three types of shaft type, shaftless type and gantry type. The specifications vary from φ 1250 to φ 2000, and customers can choose according to their needs. | |

| 13 | Noise | Fully enclosed ≤ 80DB (1 meter away from the main engine) | |

| 14 | wire breaking rate | Under normal situation, the rate of breaking is zero | |

| 15 | Control mode (SANP patent) | Mainframe adopts SANP brand computer controller, frequency conversion control technology, the technical parameters of input in advance before operation need, when you just need to press a button, existing broken wire, cable, meter, oil pump failure, such as thermal overload alarm function, all are done by computer, and can adjust the pitch and speed at any time, obligate interface, so that the computer remote control | |

| 16 | Power of motor and frequency | 4.0 kw motor 1pcs,50HZ,380V | |

| 17 | Weight | KG | 3200 |

| 18 | pitch adjustment | automatic adjustment of pitch |

Package

Related machines

Cable Extrusion Machine Cable puller Cable Production Line Take up and Pay off Machine

Comany Profile

Our company has a technical administration team who engages wire and cable equipment industrial more than twenty years, as well as experienced engineer and skilled workers, our honest business reputation and good sales achievement, win the trust from our domestic and overseas customers, the products are exported to United States, France, Spain, Portugal, New Zealand, Brazil, Mexico, Chile, South Africa, Zambia, Egypt, South Korea, Singapore, Indonesia, Thailand, Iran, etc.

FAQ

Q:What informations should I offer to get a detailed quotation from you?

A: Rope diameter ,rope usefull, sample rope picture ,braid material,the best you know machine model or Machine photo you find from other factories or before your machine bobbin size

Q:What is the most important thing to make sure before order?

A:Machine working power: 220V/60HZ/3PHASE, 380V/50HZ/3PHASE ,440V/50HZ/3PHASE or others

Q:Can you install the machine and make the machine running stablely for us after machine arrive?

A:Our machine is mostly ready for running directly, as we already debugged the machine before shipping, you just need to follow our manual.

If neccessory, our technicians are available to service overseas,you only need to afford his air ticket, Accommodation.

Q: What should we do if the machine strike during working?

Our machine has 1 year guarantee, for easy worn down spare parts ,we have already shipped some together with the machine. In this guarantee year, these spare parts are free, you only need to pay freight cost.

We after-sales technician are always available to offer technician support by long-distance or overseas.

In some countries ,we have office or agent, you can directly ask our oversea technician to solve the problem in your factory.