- Overview

- Product Description

- Certifications

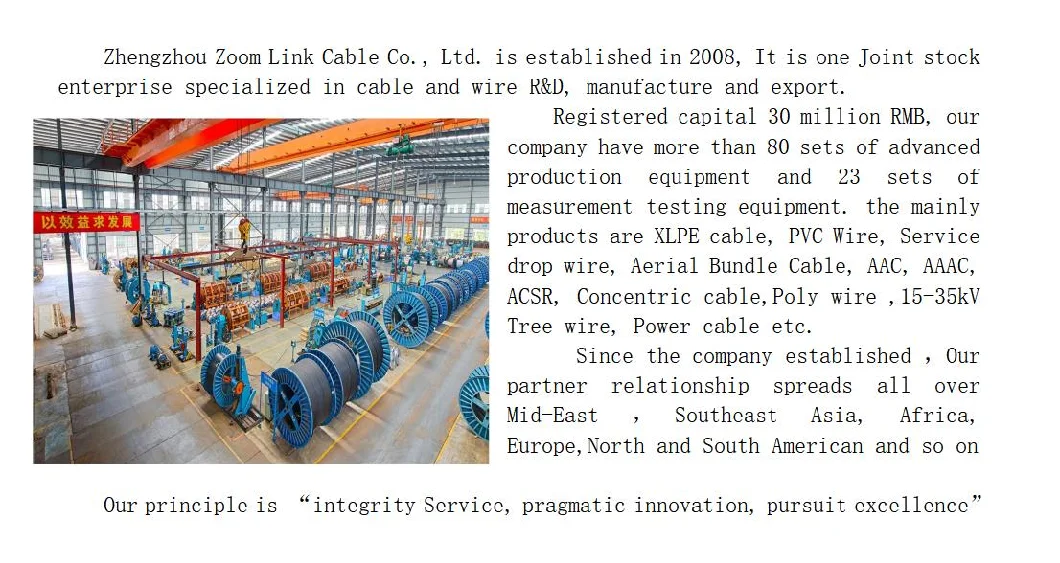

- Company Profile

- FAQ

- After Sales Service

Basic Info.

Model NO.

concentric cable

Insulation Material

XLPE

Sheath Material

PVC

Material Shape

Flat Wire

Wire Core Material

Aluminum or Copper

Certification

ISO

Model

Concentric

Brand

Zoom Link

Matrial of Conductor

AA8000, 1350 Al, Copper

Material of Insulation

XLPE or PVC

Material of Jacket

XLPE or PVC

Size

8AWG to 4/0 AWG

Core

2-4

Type of Company

Manufacture

MOQ

5000m

Quality

100% Test Each Drum

Prices

Factory Prices

Transport Package

Drum

Specification

6AWG to 4/0 AWG

Trademark

ZML

Origin

China

HS Code

8544492100

Production Capacity

10000 M Per Day

Packaging & Delivery

Package Size

100.00cm * 100.00cm * 100.00cm

Package Gross Weight

1000.000kg

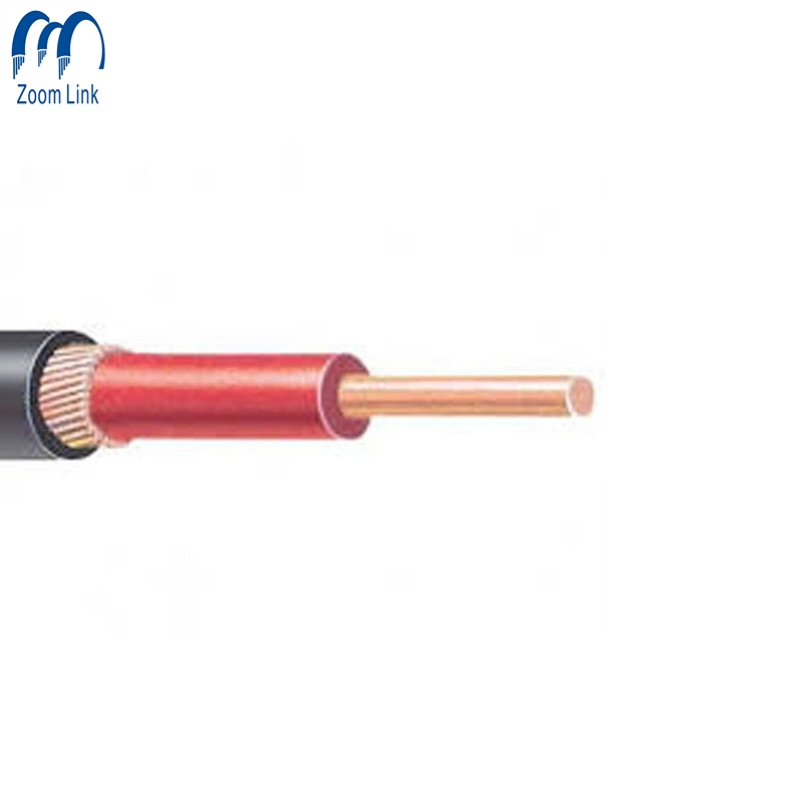

Product Description

Cobre concentrico de cable and concentric cable 2x4mm, 2x6mm ,2x10mm,

1. STANDARD

The concentric conductors of copper and aluminum, is entirely consistent with the rules ASTM D 790, D 1248, D 2655, D 2656, UL 854, UL 44, .

2. CHARACTERISTICS OF THE COPPER AND ALUMINUM CONDUCTORS

The concentric conductors of copper and aluminum, is entirely consistent with the rules ASTM D 790, D 1248, D 2655, D 2656, UL 854, UL 44,ASTM B 801, ASTM B800 .

2.1 CONSTRUCTIVE CHARACTERISTICS

Each material used in the conductor will be compatible with all other materials used in the manufacture of concentric conductor.

Concentric conductor consists of one or two conductors which in turn are coated with a bare conductor distributed helically around the conductors.

According to these configurations will have a phase and outer concentric neutral (bipolar), or two phases and these external neutral (tripolar)

Section of all conductors that form the concentric conductor of both phases as the concentric neutral is the same.

Conductor:

The materials used in the manufacture of concentric aluminum conductors formed by wires aluminum 8000 serises , or 1350 Al, or Copper

shall comply with the provisions of ASTM standard .

Isolation:

Each phase conductor will contain an insulating layer of XLPE for a temperature of 90 C. in the bipolar cables, over the insulating layer will be the braided neutral conductor helically with a passage between 8 and 16 times the outer diameter. In the tripolar cables over the isolation of each phase will have a PVC insulation filling in the joint of both cables and over this will be placed the neutral conductor.

Will be put over the concentric neutral conductor a tape and over this outer layer of PVC. Must ensure the tightness of the set plus adequate resistance to ultraviolet rays (UV),Covering the entire concentric conductor will be placed a PVC coating.

| ASTM 600/1000v | |||||||||||

| Core | AWG | Structure Size (mm) | Copper cable (kg/km) | ||||||||

| Conductor | Insulation | Concentric conductor | Outer sheath | ||||||||

| Single wire | XLPE | Single wire | UV-PVC | ||||||||

| No. | Dia. | Thick | No. | Dia. | Thick | Dia. | |||||

| 2 | 16 | 7 | 0.49 | 1.14 | 39 | 0.321 | 1.14 | 6.82 | 81.46 | ||

| 2 | 10 | 7 | 0.98 | 1.14 | 34 | 0.511 | 1.14 | 8.67 | 172.04 | ||

| 2 | 8 | 7 | 1.23 | 1.14 | 25 | 0.643 | 1.14 | 9.68 | 221.58 | ||

| 2 | 6 | 7 | 1.55 | 1.14 | 25 | 0.813 | 1.14 | 10.98 | 160.50 | ||

| 2 | 4 | 7 | 1.96 | 1.14 | 27 | 1.020 | 1.14 | 12.62 | 509.26 | ||

| IEC 60502-1 IEC 60228 600/1000v | |||||||||||

| Size (mm2) | Structure Size mm | Copper cable (kg/km) | |||||||||

| Concuctor | Insulation | Concentric conductor | Outer sheath | ||||||||

| Single wire | Dia. | PVC | Single wire | UV-PVC | |||||||

| No. | Dia. | Thick | No. | Dia. | Thick | Dia. | (kg/km) | ||||

| 10 | 7 | 1.35 | 4.05 | 1.55 | 20 | 0.85 | 1.4 | 11.79 | 301.55 | ||

| 16 | 7 | 1.7 | 5.1 | 1.55 | 32 | 0.85 | 1.4 | 12.84 | 431.7 | ||

| 25 | 7 | 2.14 | 6.42 | 1.6 | 29 | 1.13 | 1.5 | 15.02 | 647.46 | ||

| 16 | 7 | 1.7 | 5.1 | 1.55 | 26 | 1.13 | 1.4 | 13.42 | 244.16 | ||

| 25 | 7 | 2.14 | 6.42 | 1.6 | 29 | 1.13 | 1.5 | 15.02 | 307.3 | ||

| 35 | 19 | 1.53 | 7.65 | 1.65 | 27 | 1.35 | 1.6 | 16.99 | 390.15 | ||