Basic Info.

Model NO.

885000

Metal Wire Drawing

Cold Drawing

Status

Soft State

Thickness

0.01-5mm

Certification

SGS,CE

Tensile Strength

450-2350MPa

Key Word

Stainless Wire

Feature

Antirust

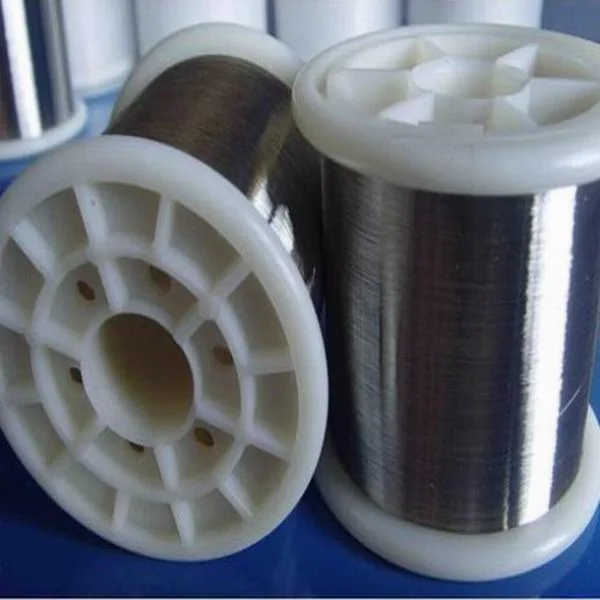

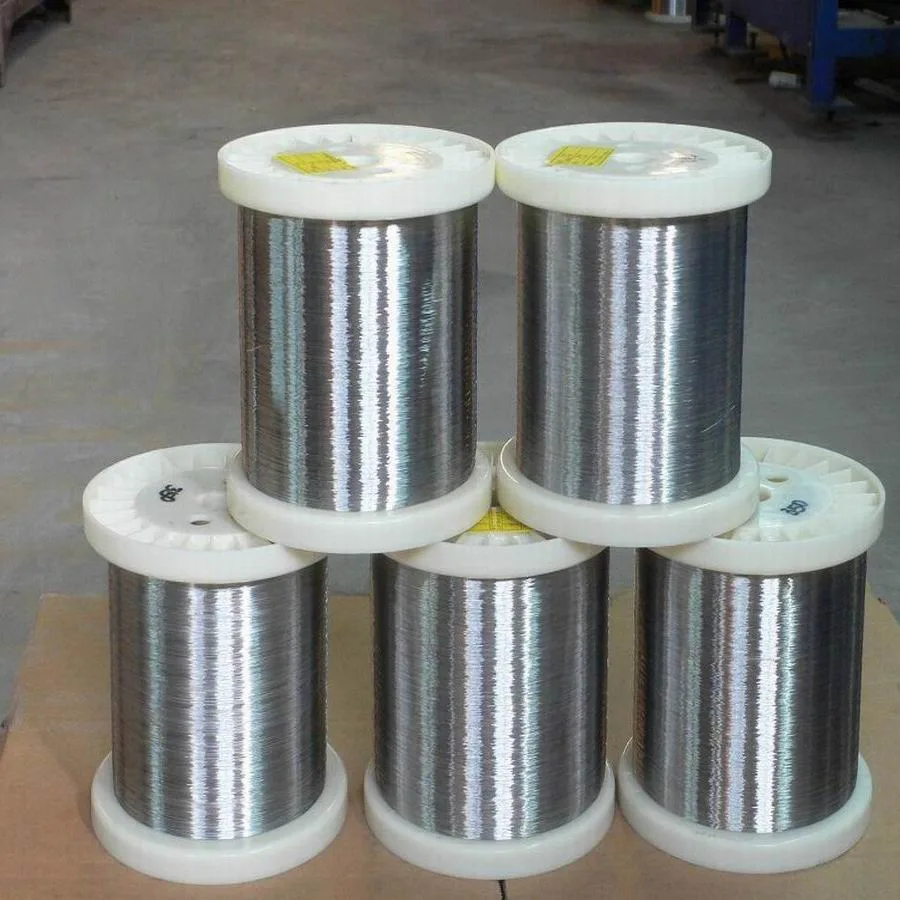

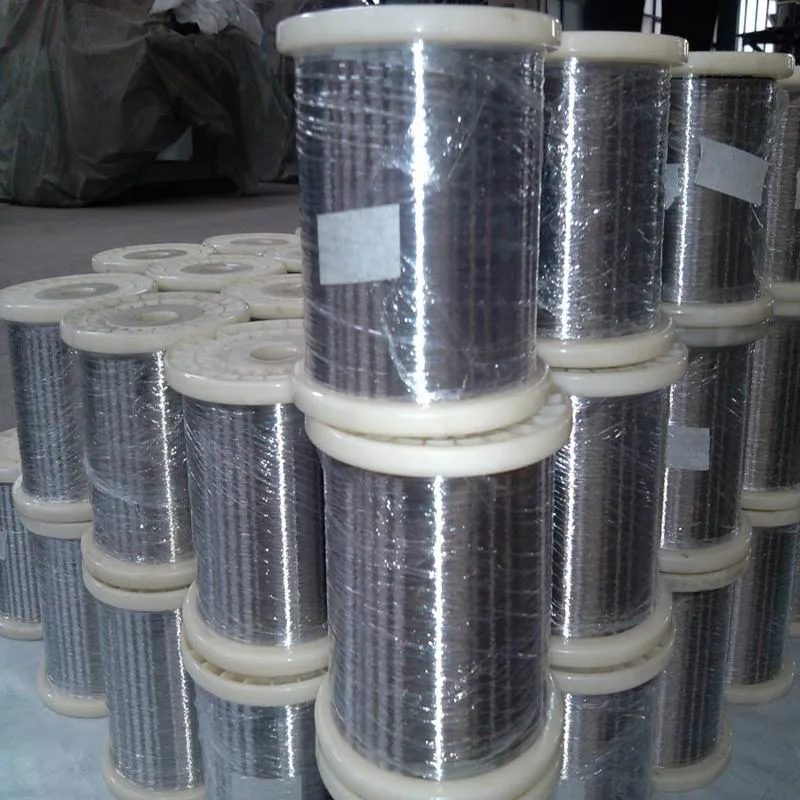

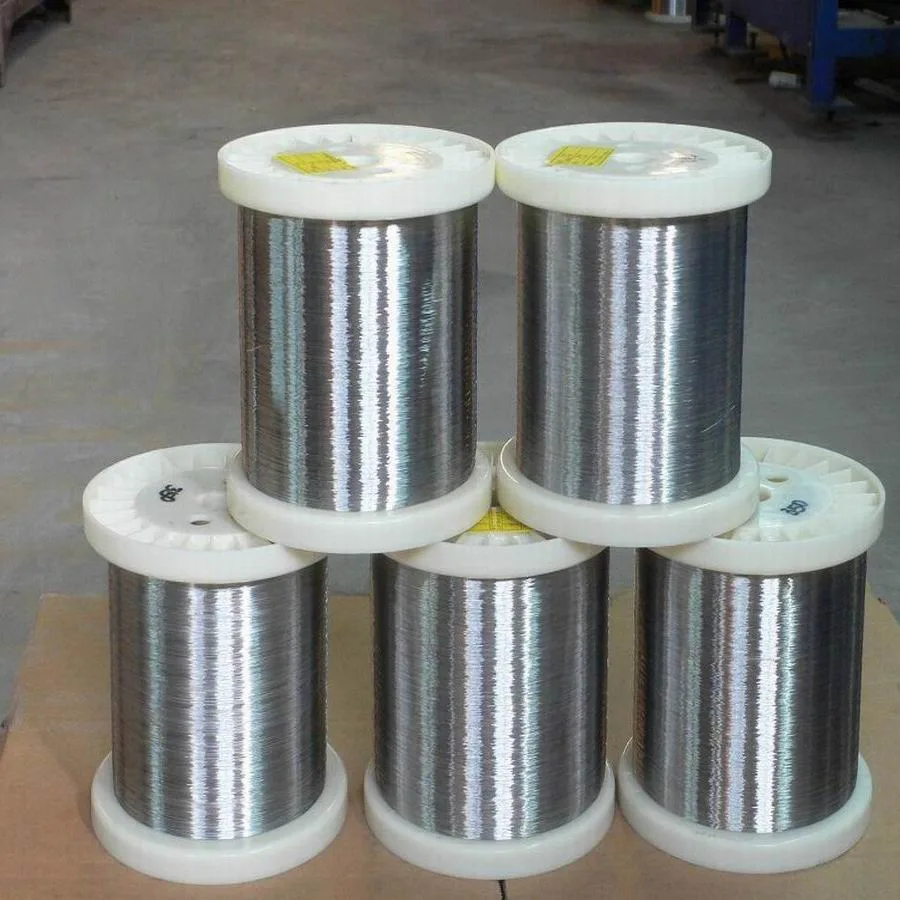

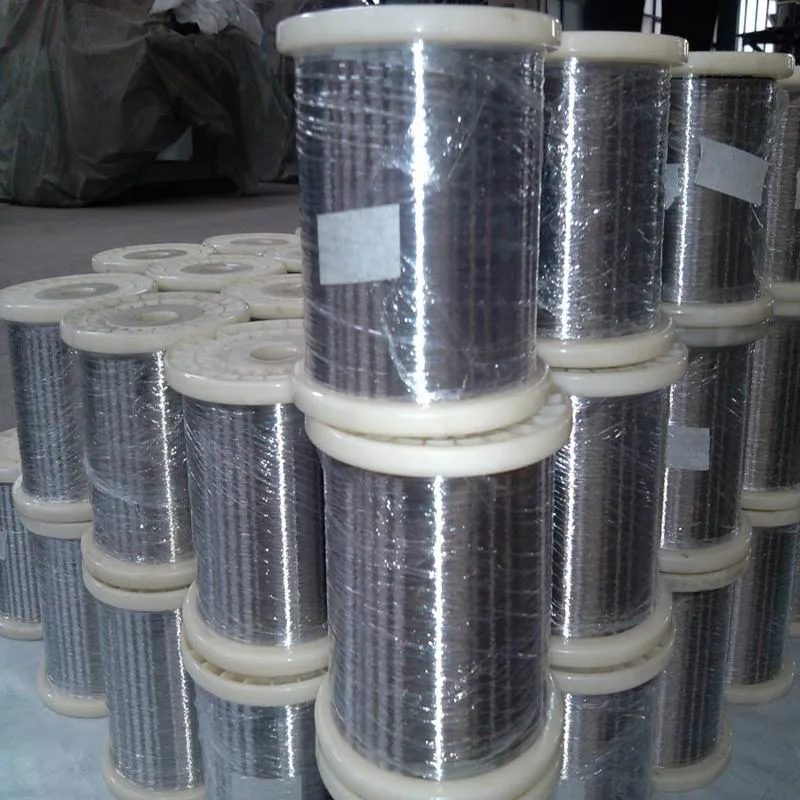

Transport Package

Roll, Spool, Pallet

Specification

0.01-5mm

Trademark

juyun

Origin

China

HS Code

7223000000

Production Capacity

200tons/Month

Product Description

Stainless Steel wires

Materials : SUS201,202,302,304,304L,430,316,316L,310S,321etc.

Diameter:0.01mm-12mm

Category:hard wire,soft wire,stainless steel sharft thread

Characteristic of stainless steel wire :

a.Excellent straightness

b.Uniform and beautiful surface condition

c.Excellent coil forming ability

d.High elasticity and high fatigue resistance

e.Strong corrosion resistance against exposure to the toughest atmosphere

Aplication:stainless steel wire mainly used in a number of industries including wire-drawing,weaving of wire mesh,soft pipe,beam of cabinet,steel wire rope,filter material and equipment,spring,making of handcrafts,etc

Materials : SUS201,202,302,304,304L,430,316,316L,310S,321etc.

Diameter:0.01mm-12mm

Category:hard wire,soft wire,stainless steel sharft thread

Characteristic of stainless steel wire :

a.Excellent straightness

b.Uniform and beautiful surface condition

c.Excellent coil forming ability

d.High elasticity and high fatigue resistance

e.Strong corrosion resistance against exposure to the toughest atmosphere

Aplication:stainless steel wire mainly used in a number of industries including wire-drawing,weaving of wire mesh,soft pipe,beam of cabinet,steel wire rope,filter material and equipment,spring,making of handcrafts,etc

| The basic information: | |||

| An English name: | stainless steel wire | The characteristics of: | Surface light, beautiful and durable |

| application: | In weaving woven wire mesh | The material: | 302,304,304L |

| The basic information: stainless steel silk, corrosion resistance, acid and alkali resistant, high temperature resistant, not easy to wear, not easy ageing, good toughness and high strength etc. | |||

| Wire diameter:(mm) | Allowable differential:(mm) | Maximum differential partial diameter:(mm) |

| 0.2-0.59 | + 0.01 / - 0.01 | 0.02 |

| 0.6-0.99 | + 0.01 / - 0.02 | 0.03 |

| 1.0-1.49 | + 0.2 / - 0.2 | 0.04 |

| 1.5-1.99 | + 0.02 / - 0.03 | 0.05 |

| 2.0-2.49 | + 0.03 / - 0.03 | 0.06 |

| 2.5-2.99 | + 0.03 / - 0.04 | 0.07 |

| 3.0-3.5 | + 0.03 / - 0.05 | 0.08 |

| 3.5-4.0 | + 0.04 / - 0.05 | 0.09 |

| 4.1-6.0 | + 0.05 / - 0.05 | 0.10 |

| Chemical composition:(%) |

| AISI material | 304 | 304L | 304HC | 316 | 316L | 310S | 321 | 301 | 302 |

| C | <0.08 | <0.03 | <0.06 | <0.08 | <0.03 | <0.08 | <0.08 | <0.15 | <0.15 |

| Si | <1.0 | <1.0 | <1.0 | <1.0 | <1.0 | <1.5 | <1.0 | <1.0 | <1.0 |

| Mn | <2.0 | <2.0 | <2.0 | <2.0 | <2.0 | <2.0 | <2.0 | <2.0 | <2.0 |

| P | <0.035 | <0.04 | <0.035 | <0.04 | <0.04 | <0.04 | <0.045 | <0.04 | <0.04 |

| S | <0.03 | <0.03 | <0.03 | <0.03 | <0.03 | <0.03 | <0.03 | <0.03 | <0.03 |

| Ni | 8~10 | 9~13 | 8~11 | 10~14 | 12~15 | 19~22 | 9~13 | >7 | >8 |

| Cr | 17~1 | 18~20 | 17~19 | 16~18 | 16~18 | 24~26 | 17~19 | 16~18 | 17~19 |

| Mo | - | - | - | 2.0~3.0 | 2.0~3.0 | - | - | - | - |

| Cu | - | - | 2.0-3.0 | - | - | - | - | - | - |

| Ti | - | - | - | - | - | - | - | - | - |